In industries where precision, safety, and efficiency are paramount, the ability to inspect machinery and infrastructure without disassembly is a game-changer. Industrial inspection cameras, including tools like the borescope, have become essential devices in modern maintenance and repair practices. From aviation to plumbing, these advanced optical instruments are transforming how technicians and engineers approach diagnostics, troubleshooting, and preventive maintenance.

A Clear View Without Disassembly

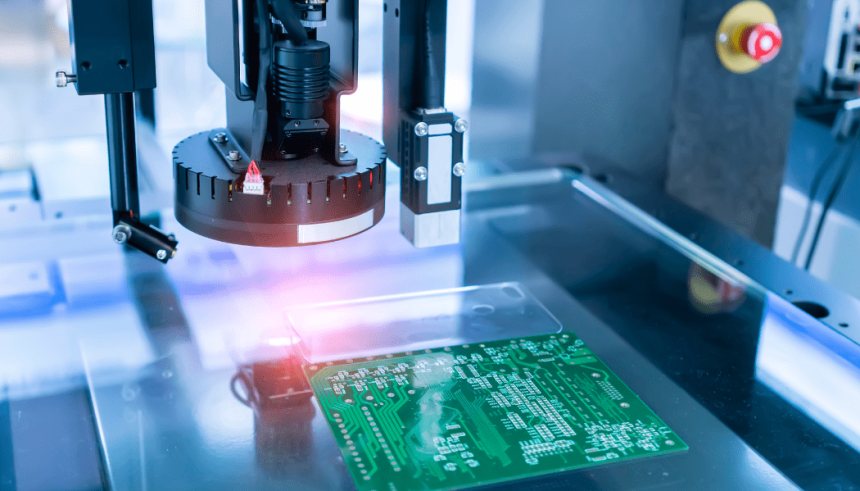

Traditionally, diagnosing internal faults within machinery or hard-to-reach areas required invasive techniques. That often meant tearing down complex assemblies, costing valuable time and exposing systems to further risk. Industrial inspection cameras now provide an elegant solution. Devices like borescopes, videoscopes, and pipe cameras allow users to visually inspect the interior of equipment, pipes, walls, and engines through small openings, saving both time and effort.

A borescope, for example, is a flexible or rigid device equipped with a high-resolution camera and light source at its tip. It transmits images to a display screen, allowing technicians to view internal components with clarity. With minimal disruption to operations, these tools deliver precise visual insights that would be otherwise impossible to access.

Enhanced Diagnostics and Preventive Maintenance

One of the biggest impacts of industrial inspection cameras lies in preventive maintenance. Instead of waiting for a malfunction to shut down operations, technicians can proactively inspect systems for early signs of wear and tear. Cracks, corrosion, leaks, or loose components can be identified before they lead to failure.

In industries like aviation, where safety standards are strict, borescopes are routinely used to inspect turbine blades, combustion chambers, and other internal aircraft parts. In manufacturing, they help monitor the integrity of welding seams, castings, and machinery components. These early detections help prevent costly breakdowns and extend the life of equipment.

Boosting Accuracy and Reducing Downtime

Downtime is a critical issue across many sectors. Whether it’s an automotive assembly line or a power plant, halting operations due to repair work can lead to massive losses. Inspection cameras minimize this risk by allowing quick and accurate diagnostics. Once the issue is located, repair teams can focus their efforts exactly where needed, eliminating guesswork.

The clarity of imagery provided by modern inspection cameras ensures greater accuracy in identifying problems. With some borescopes offering 360-degree articulation and HD image capture, even the smallest faults can be detected. This precision improves repair quality and shortens repair cycles.

Versatility Across Industries

Industrial inspection cameras are no longer reserved for niche applications. Their use has expanded across sectors such as oil and gas, HVAC, construction, water treatment, and even agriculture. For example, in the plumbing industry, pipe inspection cameras can navigate through drains and sewer lines to pinpoint blockages, tree root intrusions, or collapsed pipe sections. In building maintenance, inspection cameras help locate electrical faults behind walls or in tight crawl spaces.

This versatility makes inspection cameras a smart investment for any technician or business that deals with machinery, infrastructure, or confined spaces. Some advanced models also include features like digital recording, wireless transmission, and measurement tools, making them even more powerful in fieldwork.

The Future of Smart Maintenance

As industrial technology evolves, so do inspection tools. The future will likely bring further integration of AI and machine learning into inspection systems. These advancements could allow real-time defect detection and automated reporting, improving both the speed and consistency of inspections.

In conclusion, tools like the borescope and other industrial inspection cameras have dramatically changed the way professionals handle maintenance and repair. They empower teams to work smarter, not harder—reducing downtime, improving accuracy, and preventing catastrophic failures before they happen. As more industries recognize their value, these tools will continue to play a central role in efficient and effective maintenance strategies.