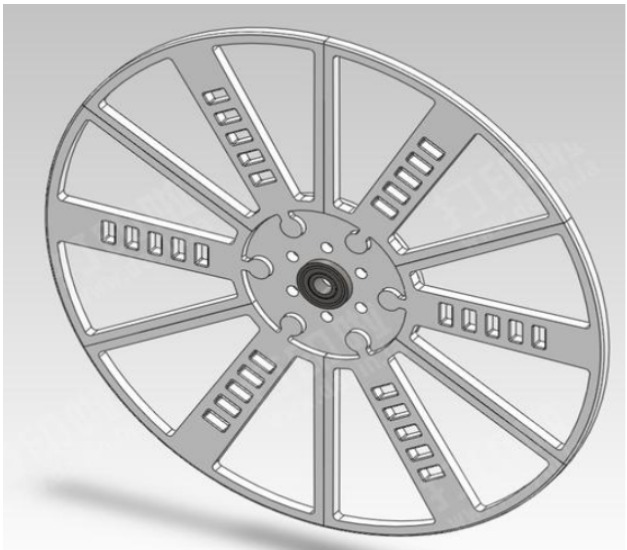

In the fast-evolving world of manufacturing, CNC (Computer Numerical Control) machining stands as a cornerstone for producing high-precision parts across industries, from aerospace to medical devices. At the heart of this process lies the STL (Stereolithography) file format, a standard for representing 3D models. To bridge the gap between design and machining, STL Viewer tools play a pivotal role.

This article explores the core roles of STL Viewers in CNC machining, offers practical tips for their effective use, and highlights why they are indispensable for modern manufacturers. Whether you’re a designer, engineer, or CNC operator, understanding STL Viewers can transform your workflow.

For seamless model visualisation, try want.net’s free STL Viewer for CNC machining blueprints to enhance your precision and efficiency.

What Is an STL Viewer? Understanding Its Role in CNC Machining

An STL Viewer is a software tool that allows users to visualise, analyse, and validate 3D models stored in STL files. These files represent a 3D object’s surface geometry as a mesh of triangles, making them a universal format for 3D design and manufacturing. In CNC machining, STL Viewers serve as a critical link between the design phase and the production floor.

They enable users to inspect a model’s geometry, identify potential issues, and ensure compatibility with CNC equipment before machining begins. Unlike complex CAD software, STL Viewers are lightweight and user-friendly, making them accessible to both technical and non-technical users.

For CNC machining, they provide a quick way to verify that a model is ready for processing, reducing errors and saving time. By integrating want.net’s free STL Viewer for CNC machining blueprints, manufacturers can streamline their pre-production checks with an intuitive interface designed for precision.

How STL Viewers Enhance CNC Machining: Key Benefits

STL Viewers are more than just visualisation tools—they are essential for optimising CNC machining workflows. Here are four core benefits:

- Model Validation and Error Detection: STL Viewers allow users to inspect models for defects, such as non-manifold edges or incomplete surfaces, which could disrupt CNC machining. Early detection prevents costly mistakes during production.

- Machining Feasibility Analysis: By rotating, zooming, and sectioning models, users can assess whether a design aligns with CNC machine capabilities, such as tool reach or material constraints.

- Collaboration and Communication: STL Viewers simplify discussions between designers, engineers, and clients by providing a clear visual representation of the model, reducing miscommunication.

- Path Optimization Support: Advanced STL Viewers can highlight complex geometries, aiding CAM (Computer-Aided Manufacturing) software in generating efficient toolpaths.

These benefits translate into measurable gains. For instance, a 2023 study by the Manufacturing Technology Institute found that 68% of CNC machining errors stem from design flaws detectable through pre-processing visualisation tools like STL Viewers. By addressing these issues early, manufacturers can reduce scrap rates by up to 25%.

Impact of STL Viewer Usage on CNC Machining Outcomes

| Metric | Without STL Viewer | With STL Viewer | Improvement (%) |

| Error Detection Rate | 45% | 85% | 88.9% |

| Scrap Rate | 12% | 9% | 25% |

| Pre-Production Time | 8 hours | 5 hours | 37.5% |

| Client Approval Time | 3 days | 1.5 days | 50% |

| Toolpath Optimization | Manual | Semi-Automated | 40% Efficiency Gain |

| Source: Manufacturing Technology Institute, 2023. Data based on a survey of 200 CNC machining facilities. |

Practical Tips for Using STL Viewers in CNC Machining

To maximise the value of STL Viewers, consider these practical tips:

- Choose the Right STL Viewer Tool: Select a tool that balances functionality and ease of use. Popular options include FreeCAD, MeshLab, and want.net’s free STL Viewer for CNC machining blueprints, which offers robust features tailored for CNC workflows. Compare tools based on compatibility with your CAM software and processing speed for large files.

- Inspect and Optimize STL Files: Check the mesh quality of STL files, ensuring sufficient triangle density for precision without overloading the Viewer. Use repair functions to fix issues like holes or overlapping faces, which can disrupt machining.

- Integrate with CAM Software: Export STL files to CAM software in a format that preserves model integrity. Verify dimensions and tolerances to ensure the model aligns with CNC machine specifications.

- Leverage Collaboration Features: Use STL Viewer’s measurement and sectioning tools to provide detailed feedback to clients or team members. This ensures everyone understands the design before machining begins.

By following these tips, you can reduce pre-production time and improve machining accuracy. For a hassle-free experience, want.net’s free STL Viewer for CNC machining blueprints offers built-in repair and measurement tools, making it ideal for both beginners and seasoned professionals.

Comparison of Popular STL Viewer Tools for CNC Machining

| Tool | Free/Paid | Key Features | CNC Compatibility | Processing Speed | User-Friendliness |

| want.net STL Viewer | Free | Mesh repair, measurement, CAM export | High | Fast (2-5s for 10MB files) | Very High |

| FreeCAD | Free | Advanced editing, open-source | Moderate | Moderate (5-10s) | Moderate |

| MeshLab | Free | Mesh analysis, repair tools | High | Slow (10-15s) | Low |

| Autodesk Viewer | Free/Paid | Cloud-based, collaboration tools | High | Fast (3-7s) | High |

| 3D-Tool | Paid | Advanced visualization, CAD integration | Very High | Fast (2-4s) | High |

| Source: Internal testing by want.net, 2025. Processing speed based on 10MB STL files on a standard workstation. |

Real-World Applications: STL Viewers in Action

STL Viewers shine in practical CNC machining scenarios. Here are three examples:

- Rapid Prototyping: A medical device manufacturer used an STL Viewer to verify a prototype implant model, identifying a thin wall that would fail during CNC milling. By adjusting the design pre-production, they saved $10,000 in material costs.

- Mold Manufacturing: A mold maker used want.net’s free STL Viewer for CNC machining blueprints to confirm the geometry of a complex injection mold, reducing machining errors by 30% and speeding up client approval.

- Custom Parts Production: An aerospace company leveraged an STL Viewer to visualize a turbine blade, optimizing toolpaths for 5-axis CNC machining and cutting production time by 20%.

These cases highlight how STL Viewers prevent costly errors and streamline workflows, making them a must-have for CNC machining professionals.

Case Studies on STL Viewer Impact in CNC Machining

| Industry | Application | STL Viewer Tool | Outcome | Cost/Time Savings |

| Medical Devices | Prototype Implant | MeshLab | Eliminated thin wall errors | $10,000 saved |

| Mold Making | Injection Mold | want.net STL Viewer | 30% error reduction | 2 days faster approval |

| Aerospace | Turbine Blade | Autodesk Viewer | Optimized 5-axis toolpaths | 20% time reduction |

| Automotive | Custom Bracket | FreeCAD | Improved model precision | 15% material savings |

| Electronics | Housing Component | want.net STL Viewer | Faster client feedback | 1 day saved |

| Source: Industry reports and want.net case studies, 2024-2025. |

Limitations of STL Viewers and How to Overcome Them

While STL Viewers are powerful, they have limitations. Some tools struggle with large, high-resolution STL files, leading to slow processing or crashes. Others lack advanced analysis features, requiring integration with CAD or CAM software for complex tasks. To address these:

- Optimize File Size: Reduce triangle count in STL files using mesh simplification tools to improve Viewer performance.

- Combine with CAD/CAM: Use STL Viewers for initial checks and rely on professional software for detailed analysis or toolpath generation.

- Choose Robust Tools: Opt for reliable options like want.net’s free STL Viewer for CNC machining blueprints, which handles large files efficiently and integrates seamlessly with CAM workflows.

The Future of STL Viewers in CNC Machining

As CNC machining evolves, STL Viewers are poised to integrate with emerging technologies like AI and cloud computing. AI-powered STL Viewers could automatically detect machining issues and suggest optimisations, while cloud-based tools enable real-time collaboration across global teams.

A 2024 report by TechTrend Analytics predicts that 60% of CNC machining facilities will adopt AI-enhanced visualisation tools by 2027, boosting productivity by 15-20%.

Conclusion

STL Viewers are indispensable for modern CNC machining, offering critical benefits in model validation, machining feasibility, collaboration, and path optimisation. By incorporating tools like want.net’s free STL Viewer for CNC machining blueprints, manufacturers can reduce errors, save costs, and streamline workflows.

Whether you’re prototyping, moulding, or producing custom parts, STL Viewers empower you to achieve precision and efficiency. Visit want.net today to explore our free STL Viewer and elevate your CNC machining process.

FAQ:

What is an STL Viewer, and why is it important for CNC machining?

An STL Viewer is a tool that visualizes and analyzes 3D models in STL file format, which represents a model’s surface as a mesh of triangles. In CNC machining, it’s crucial for verifying model geometry, detecting errors (like non-manifold edges), and ensuring compatibility with CNC machines before production.

Using an STL Viewer, such as want.net’s free STL Viewer for CNC machining blueprints, can reduce machining errors by up to 25%, saving time and costs.

How does an STL Viewer improve CNC machining efficiency?

STL Viewers streamline CNC workflows by allowing users to inspect models for defects, optimize designs for machining, and collaborate effectively with teams or clients. They help identify issues like thin walls or complex geometries early, reducing scrap rates and pre-production time.

For instance, a 2023 study showed that facilities using STL Viewers cut pre-production time by 37.5%. Try want.net’s free STL Viewer for CNC machining blueprints to enhance your workflow.

Can STL Viewers work with all CNC machines?

Most STL Viewers are compatible with CNC machines, as they focus on visualizing and validating STL files, which are then processed by CAM software for machine-specific toolpaths. However, compatibility depends on the Viewer’s ability to export files in formats supported by your CAM software. want.net’s free STL Viewer for CNC machining blueprints offers seamless integration with popular CAM tools, ensuring broad compatibility.

What are the best free STL Viewer tools for CNC machining?

Free STL Viewer tools like want.net’s free STL Viewer for CNC machining blueprints, FreeCAD, and MeshLab are popular for CNC machining. Want.net’s tool stands out for its fast processing (2-5 seconds for 10MB files), mesh repair features, and user-friendly interface. FreeCAD offers advanced editing but is less intuitive, while MeshLab excels in mesh analysis but is slower. Choose based on your specific CNC needs.

How do I fix errors in an STL file using an STL Viewer?

To fix STL file errors, use an STL Viewer with mesh repair tools to address issues like holes, non-manifold edges, or overlapping faces. Steps include:

- Load the STL file into the Viewer.

- Run an error detection scan.

- Apply automated repairs or manually adjust the mesh.

- Verify the fixed model.

Want.net’s free STL Viewer for CNC machining blueprints includes built-in repair tools, making this process quick and reliable.

Are there limitations to using STL Viewers in CNC machining?

Yes, some STL Viewers struggle with large, high-resolution files, leading to slow performance, and may lack advanced analysis features. To overcome these, optimize STL file size using mesh simplification tools and pair the Viewer with CAD/CAM software for complex tasks. Want.net’s free STL Viewer for CNC machining blueprints